In addition to works associated with the injection of gas in the liquid phase, we don’t forget about the development of 4th generation sequential gas injection system (gas injected in the volatile phase). The first effect of these works are LPG/CNG injectors series DGI GM.

TECHNICAL SPECIFICATION OF DGI GM INJECTORS IN STANDARD VERSION

INJECTOR DGI GM1

Injector GM1 is the injector piston design with in-line gas supply. Flow adjustment is done by a couple of calibration nozzles – simply drill nozzles to the correct size. Injectors of this type can be used in most systems with sequential injection of LPG in the vapor phase and arrangements CNG systems powered with metane.

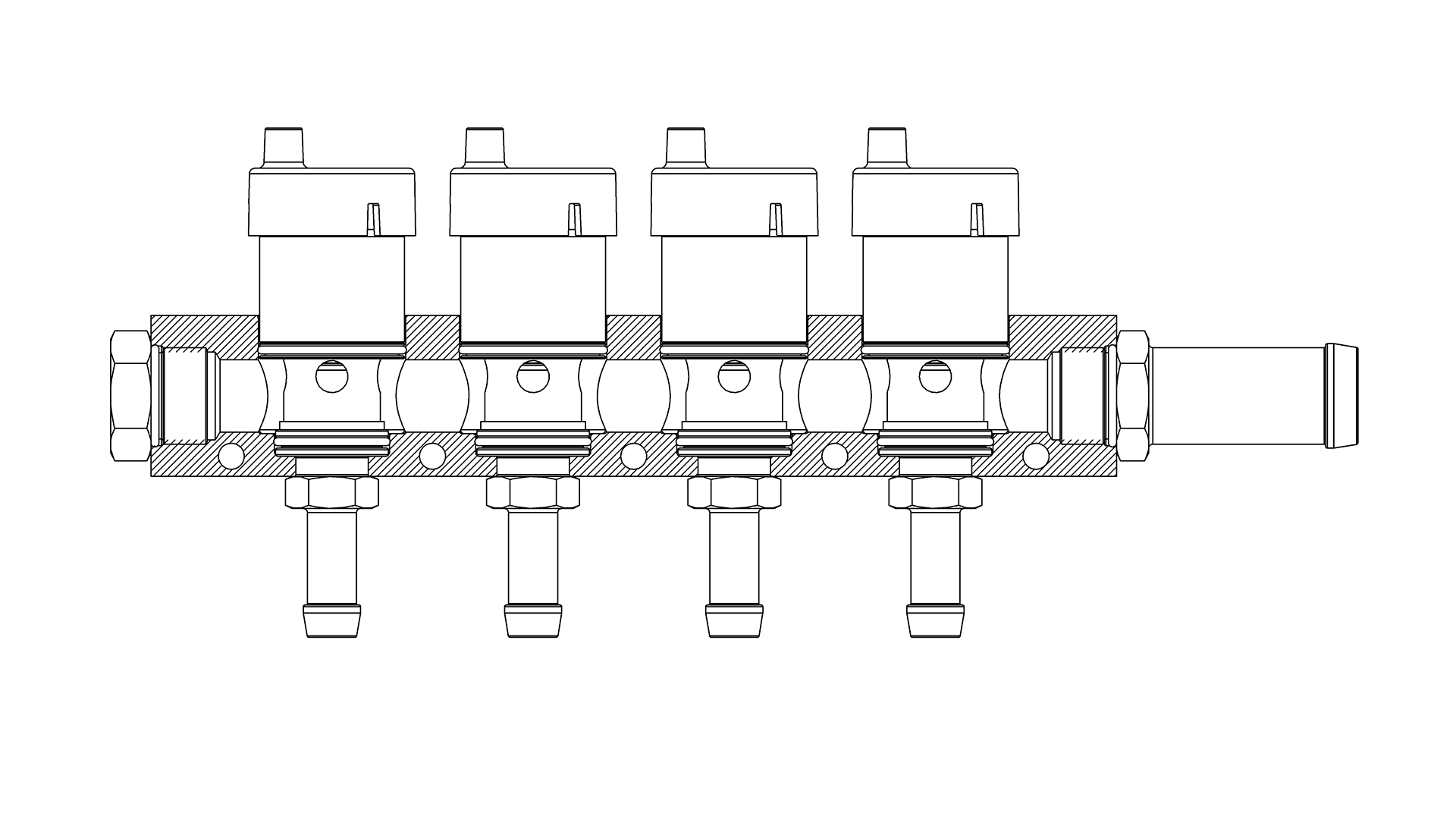

INJECTORS DGI GM2/GM3/GM4

Injectors DGI GM2/GM3/GM4 are piston-designed with side gas supply. Flow adjustment is done by a couple of calibration nozzles – simply drill nozzles to the correct size. Injectors of this type can be used in most systems with sequential injection of LPG in the vapor phase and arrangements CNG systems powered with metane.