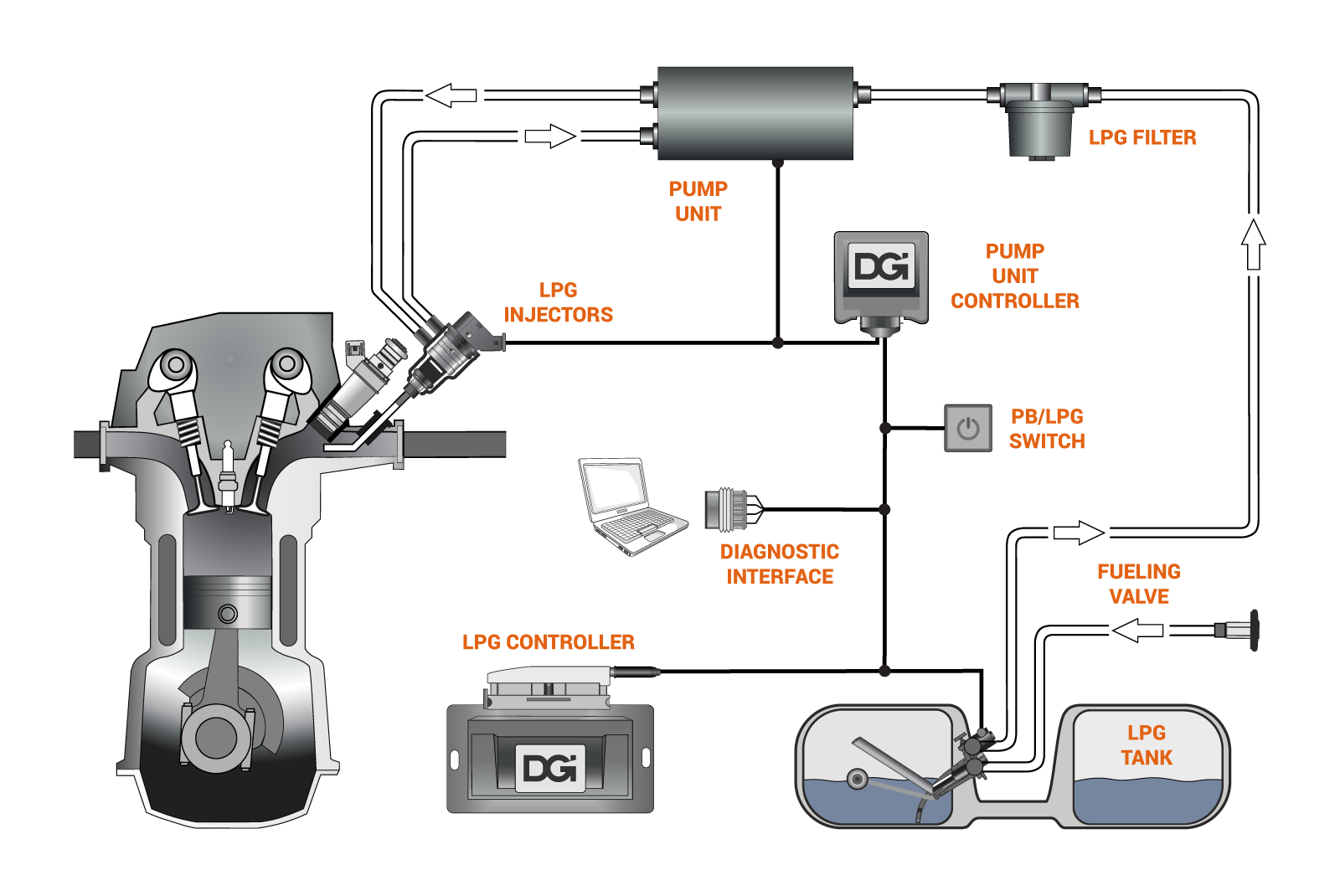

5th Generation Installation

The DGI LM is 5th generation installation, wherein the LPG in the liquid phase is injected sequentially through additional LPG injectors into the intake manifold (hence the name LM system: L is for Liquid, M is for Manifold). Liquid gas expands in the intake manifold. During the expansion process a change of LPG state from liquid to volatile is accompanied by a drop of more than 40 degrees Celsius. Then, the installation does not require the use of lubricant equipment in cars that may have a problem with the roasting valve seats. This system can be successfully installed in engines, which poorly tolerated LPG in volatile phase.

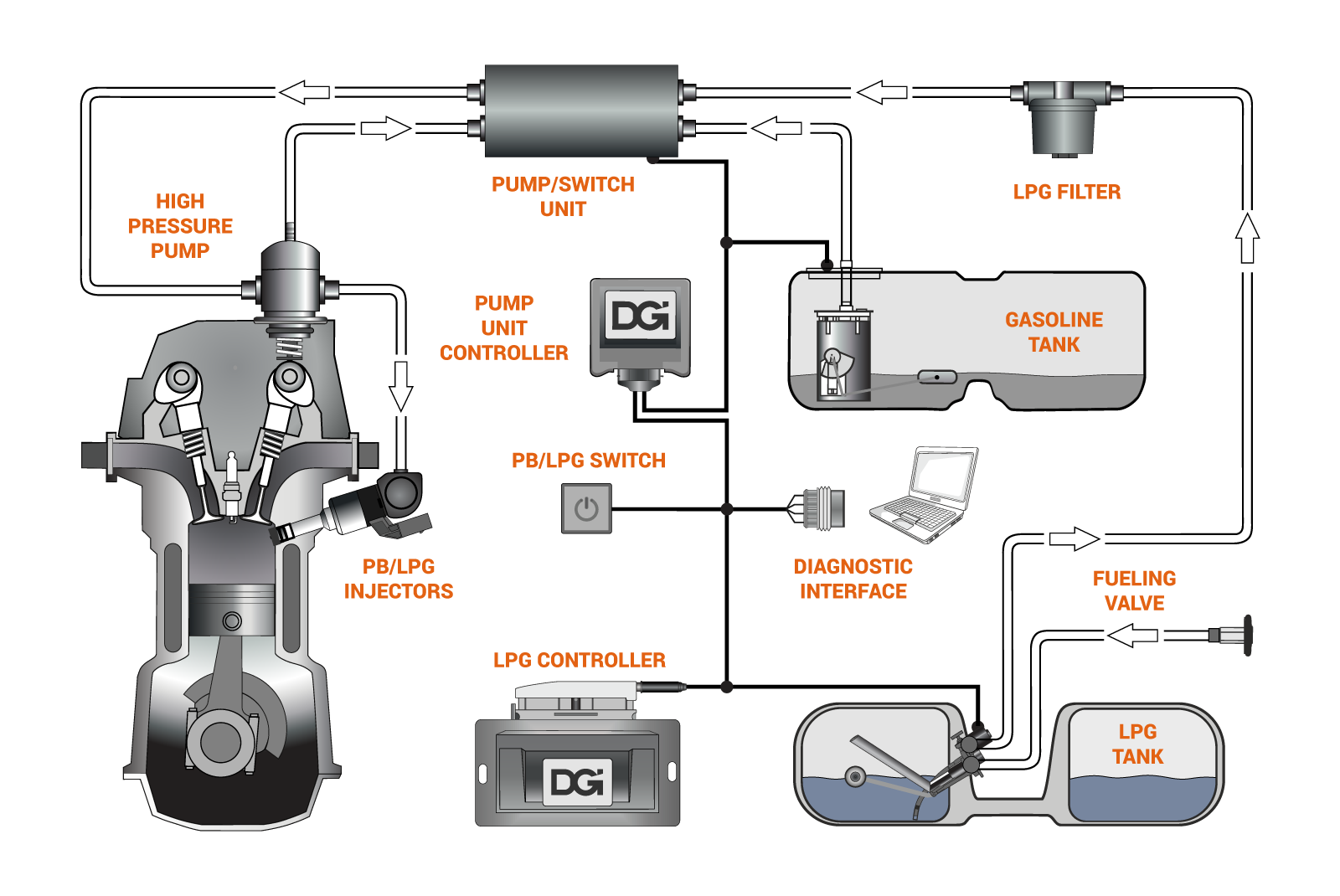

6th Generation Installation

The DGI LCC is 6th generation installation, which is ideal for engines with direct gasoline injection as it uses the original petrol injectors to inject LPG directly into the combustion chamber (hence the name of the system LCC: L is for Liquid, CC is for Combustion Chamber). When the engine operates, gasoline is not consumed at all as fuel injectors are constantly cooled by the flowing LPG and there is no need for additional gasoline injections, which from an economic point of view, nullify the meaning of conversion. The use of petrol injectors for gas injection also results in less interference in the area of the engine and the whole system is practically invisible under the hood of the car.

Advantage of installing 5th and 6th generation is the fact that they do not interfere with the cooling system of the car and that they are not sensitive to external factors such as humidity, temperature and atmospheric pressure. Interestingly, by lowering the temperature in the combustion chamber systems, 5th and 6th systems enable in general conditions to improve engine performance in the upper RPM range.

The competitive advantages of DGI LCC and DGI LM systems

- Expanded range of the vehicle. The fact of moving the fuel pumps outside the LPG tank is implying a very important exploitation aspect – it increases the vehicle’s range about 25- 35%. It comes from a fact that depending on LPG tank’s capacity, the volume of pumped units immersed into that tank may amount even up to 30% of its work volume, which in the our solution, could be filled with liquefied gas.

- The construction of competitive systems does not allow using it in vehicles where engines have a power higher than 200 HP. This happens because the competitors have used LPG pumps immersed in LPG tank. These pumps, due to its specific construction, are not able to deliver the proper quantities of fuels. The DGI solutions will benefit from external LPG pumps which will theoretically be able to support the engines with a power over 500 HP.

- DGI LCC and DGI LM systems shall cooperate with standard LPG tanks and LPG multivalves – this way the customer will receive a final product in a very attractive price while an assembling workshop or a distributor won’t have to keep additional, very expensive components – tanks and multivalves.

- The universality of DGI LCC system (VI generation, direct injection of the petrol). Competitive IV generation systems are products which serve only particular engine codes. The engine codes differ very often only in fitting used, which does not have any importance from a point of view of the LPG system assembly idea. Assigning for a particular code the one system configuration, cuts down the potential receivers. It comes from a fact that competitive companies have prepared, based on our estimates, an offer for only about 5% of all possible engines with petrol’s direct injection. The estimation of those 5% took over 5 years for competition, and new engine codes are still being prepared…

- In solutions which are now available on the market some unwanted LPG leaks may occur into the petrol tank, and petrol into LPG tank. The effect of petrol mixing is very difficult engine start, and in particular situations it may affect even a long immobilisation of a vehicle. In DGI company solutions we avoid such situations by using the original pumps and distributors system.

Apart from above mentioned advantages, all liquefied gas injection systems have evident advantages over IV generation systems:

- They do not interfere with the car cooling system.

- They are not sensitive to external factors such as humidity, temperature and atmospheric pressure because of the constant pressure maintained by the LPG pump; injectors have a linear operation.

- By lowering the temperature in the combustion chamber, the systems, in favorable conditions, enable to improve engine performance in the upper RPM range. The effect of temperature reduction is very similar to that resulting from the application of the intercooler in air supplying systems in turbo engines.

- They ensure the protection of valves and valve seats. Explanation: the composition of LPG is not only propane and butane, but also impurities that are precipitated at the time of change of state from liquid to volatile. In the case of gas supplied systems in the volatile phase they are accumulated in the evaporators and the injectors causing their slow degradation. In the case of gas injection in a liquid phase change of state occurs just before the combustion chamber (DGI LM) and in the same combustion chamber (DGI LCC) so all the impurities are burnt and finally form oxides, which also settle on the valves and valve seats and form a barrier similar to that which arises when the engine is fueled with gasoline.